How A Lab Emulsifying Mixer Works And Its Key Applications

A lab emulsifying mixer mixes liquids that do not blend together. It makes them into smooth mixtures called emulsions. The mixer does many jobs like mixing, breaking up, and dissolving things. It uses a blade that moves fast and creates strong forces. Some mixers use vacuum technology to make the mixture more stable. These mixers are very important in many industries, as shown below:

| Industry | Key Role |

|---|---|

| Pharmaceuticals | Making drugs and keeping samples stable |

| Cosmetics | Creating skincare and personal care products |

| Food & Beverages | Improving texture and taste |

| Chemicals | Making paints, glues, and special chemicals |

Key Takeaways

Lab emulsifying mixers make smooth mixtures. They break down liquids that do not mix well.

The mixers use fast blades and vacuum systems. These tools take out air bubbles. They help products stay the same and last longer.

Many industries use these mixers. Some examples are pharmaceuticals, cosmetics, food, and chemicals. Mixers help make products better and more even.

You can change the speed on these mixers. They have smart controls and cleaning systems. This makes them easy to use and good for small batches.

These mixers work in many ways and save energy. Labs can work faster and waste less. They help labs get better results every time.

Lab Emulsifying Mixer Operation

Core Components

A lab emulsifying mixer has many parts that work together.

Homogenizer Tank: This tank holds all the ingredients. It keeps them safe when pressure and temperature are high.

Rotor-Stator Assembly: The rotor spins fast inside the stator. Liquids move through a small space. This makes strong forces. Big droplets break into tiny ones.

Vacuum System: This system takes air out of the mixing chamber. It stops bubbles from forming. The mixture stays smooth.

Impellers: These blades spin at different speeds. They push materials up and down. This helps mix everything evenly.

Multi-shaft Mixers: These mixers have more than one shaft. They mix fast and control small particles.

Control Systems: Sensors and controls change speed and pressure. They protect sensitive ingredients. They help keep the quality steady.

All these parts let the lab emulsifying mixer work with many materials. It can mix thin liquids and thick creams.

Mixing Process

The mixing process uses high shear and vacuum to make stable emulsions.

The rotor spins very fast. It pulls liquids into the mixing chamber.

The small gap between the rotor and stator makes strong forces. These forces break big droplets into tiny ones.

The mixer spreads the tiny droplets everywhere in the mixture.

Emulsifiers can be added. They coat the droplets and stop them from joining together.

The vacuum system takes out air. This stops bubbles and keeps the mixture smooth and stable.

| Principle Aspect | Description |

|---|---|

| High Shear Operation | The rotor and stator spin quickly. They make strong shear and turbulence. This breaks up and mixes liquids that do not blend easily. |

| Vacuum Operation | The vacuum takes out air. It helps make bubble-free and stable emulsions. |

| Circulation through High-Shear Head | The mixer pulls materials in, shears them, and pushes them out. This repeats and makes the mixture even and fine. |

Lab emulsifying mixers do many jobs. They mix, emulsify, homogenize, disperse, and dissolve. The high shear forces and vacuum help make tiny droplet sizes. They stop the mixture from separating. This is important for making creams, lotions, and medicines. These products need to stay smooth and stable.

Key Features

Lab emulsifying mixers have special features that make them different.

External vertical inline homogenizer with pipes for strong mixing and easy product transfer

Cooling system for the mechanical seal. This lets mixing go on longer.

Push button control panel for easy use

Contra mixing system with fixed impellers and wall scraper for better blending

Outer anchor agitator with pipes for better mixing and appearance

Built-in vacuum system to remove air bubbles and help move ingredients

Adjustable speed and heating/cooling functions for precise control

Cleaning systems (CIP and SIP) to keep the mixer clean and keep product quality high

These features help the mixer make fine, even droplets and smooth mixtures. The mixer works fast and can handle thin or thick materials. It can process small batches for testing or development. The vacuum system and high shear mixing make the final product more stable and uniform. Modern mixers use smart technology and digital controls. This improves safety, efficiency, and consistency.

Lab emulsifying mixers make finer and more even emulsions than many other mixers. They help products stay stable and smooth for a long time.

Applications

Lab emulsifying mixers are used in many industries. They help make products smooth and safe. These mixers are important for research and making small batches. Every field needs products to be the same and stable. This makes sure each batch is good quality.

Pharmaceuticals

Pharmaceutical companies use these mixers to make medicines. They mix active ingredients with other things. This makes emulsions, suspensions, and dispersions. Some products are ointments, gels, creams, eye drops, and liquid medicines. Big companies like Johnson & Johnson and Pfizer use these mixers. The mixers help medicines stay stable and control how they work in the body. They take out air bubbles and protect sensitive ingredients. The vacuum and temperature control help stop contamination. This keeps every batch the same.

Make emulsions, suspensions, and dispersions

Help medicines stay stable and work better

Mix ointments, creams, gels, and eye drops

Take out air bubbles and stop oxidation

Cosmetics and Personal Care

Cosmetic brands use these mixers to make lotions, creams, shampoos, and makeup. The mixers blend oils, water, and powders together. This makes the products smooth and without lumps. They make particles smaller, so the texture and stability get better. Automated mixing helps stop mistakes and keeps products clean. Companies can go from lab samples to big batches. Each batch stays the same.

Work faster and better

Make products even and high quality

Lower the chance of contamination

Mix many types of ingredients

Food and Beverage

Food makers use these mixers for sauces, dressings, dairy, and drinks. The mixers break down particles and mix everything well. This gives smooth textures and even flavors. High-shear mixing saves time and keeps nutrients in the food. The mixers also stop the mixture from separating. This helps with quality control.

Make stable sauces and dressings

Give smooth textures in dairy and drinks

Help with quality control and making more

Chemical and Biotech

Chemical and biotech labs use these mixers for research and new products. The mixers help scientists test new ideas and make small batches. The vacuum keeps air and germs out. This keeps the products pure and stable. Advanced controls let scientists make small changes. This helps move from lab tests to bigger batches.

Make new samples and small batches fast

Stop contamination and oxidation

Help with new ideas and making more

All these industries need products to be the same and stable. High shear and vacuum mixing help make even mixtures. This lowers mistakes and meets strict quality rules.

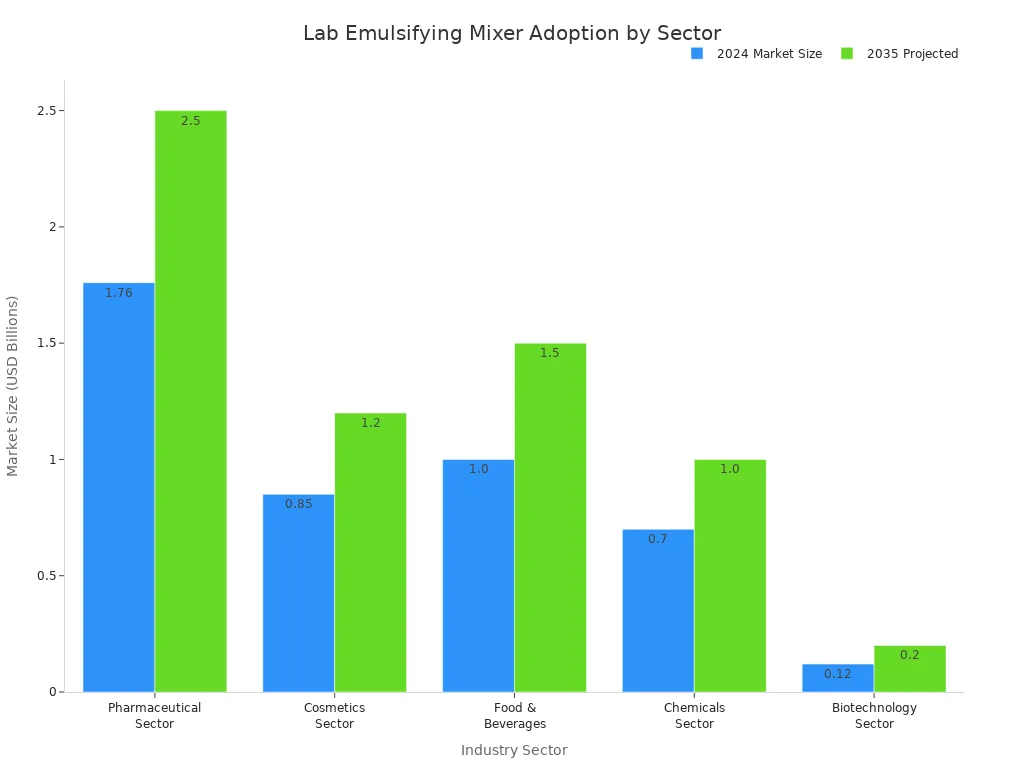

| Industry | 2024 Market Size (USD) | 2035 Projected (USD) |

|---|---|---|

| Pharmaceuticals | 1.76 billion | 2.5 billion |

| Cosmetics | 0.85 billion | 1.2 billion |

| Food & Beverages | 1.0 billion | 1.5 billion |

| Chemicals | 0.7 billion | 1.0 billion |

| Biotechnology | 0.12 billion | 0.2 billion |

Advantages

Efficiency

Lab emulsifying mixers work fast in labs and small factories.

They mix liquids quickly and evenly. This helps experiments go faster and saves time.

People can set the speed, time, and temperature exactly. This makes results more accurate and stable.

Many mixers have smart controls. These controls make the mixer easy to use and can run things automatically. This means less work for people.

Mixers can be changed to fit different experiments.

The vacuum keeps bubbles out, even when mixing fast. This makes the product better and speeds up mixing.

No bubbles make it easier to fill, measure, and store things.

A study showed that using continuous mixing instead of batch mixing saved over 49% energy. The new way also made the product better and cut down on waste. Some mixers use only 2.6 kJ of energy for each kilogram of emulsion. This shows they save a lot of energy.

Lab emulsifying mixers help labs work faster, use less energy, and make better products with less waste.

Consistency

These mixers help make every batch the same. The design and controls keep each product at a high standard.

| Feature Category | Details |

|---|---|

| High-Shear Rotor-Stator | Speed can be changed from 3,000 to 28,000 RPM. Heads can be swapped for different thicknesses. They make particles smaller, from 1 to 10 micrometers. This stops batches from being different. |

| Intelligent Controls | Shows speed on a screen, has timers you can set, and can remember settings for next time. |

| Safety & Compliance | Has safety features like overload protection and splash guards. Certified for safety. |

| Design & Scalability | Small size for lab tables, made from strong materials, and can be used for bigger jobs too. |

| Advantages | Makes results the same, works faster, easy to clean, and repeats results every time. |

Digital screens and timers help check the process.

You can watch speed and power as you mix.

Speed can be changed, and different heads can be used for thick or thin liquids.

The mixer can pump itself and is made to stay clean.

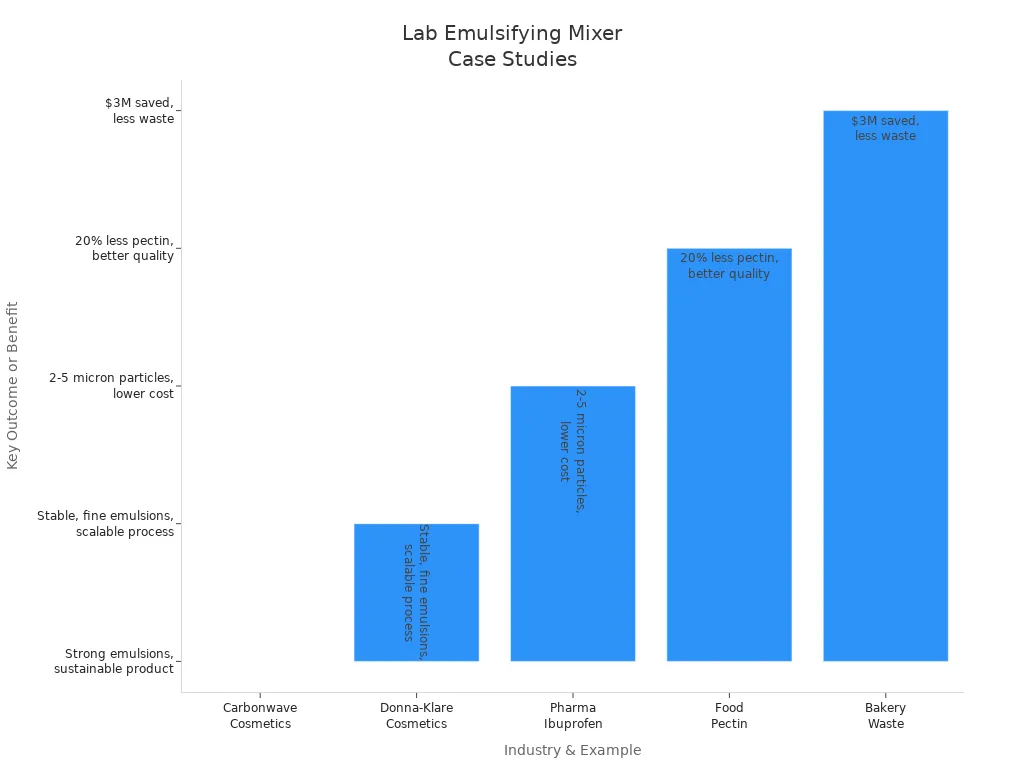

Cosmetic brands like Carbonwave and Donna-Klare use these mixers to make smooth, high-quality products every time. Medicine and battery labs also get better results and can make bigger batches more easily.

Versatility

Lab emulsifying mixers can be used for many jobs and products.

The rotor-stator makes strong forces. This helps mix liquids that do not mix well.

You can change the power and speed to fit what you need.

Digital screens and different heads let you mix many kinds of liquids.

These mixers are used in medicine, beauty, food, chemicals, and science labs.

Strong mixing and swirling help blend, spread, and break up things for many products.

| Feature Category | Description | Contribution to Versatility |

|---|---|---|

| Homogenization Technology | Uses rotor-stator, high-pressure, and ultrasonic methods. | Lets you mix many types of products with different droplet sizes and needs. |

| Material Construction | Made from strong 316L stainless steel that does not rust. | Can be used with harsh chemicals and many recipes. |

| Automation and Control | Has digital screens, settings you can program, temperature control, and remote watching. | Gives exact and repeatable mixing for different jobs. |

| Capacity | Can mix small amounts (1-5L) or bigger ones (50L+). | Good for both testing and making small batches. |

| Work Heads and Power Options | Has different heads and power levels for thick or thin liquids. | Can handle many kinds of liquids, making it very flexible. |

Many businesses use this flexibility. For example, Carbonwave made a seaweed-based cosmetic emulsifier. A bakery saved a lot of money by reusing waste. Medicine labs made better medicines. Food makers saved money and made better food.

Lab emulsifying mixers help people try new things and work better in many areas. This makes them a great tool for any lab.

A lab emulsifying mixer makes mixtures smooth and stable. It uses high shear and vacuum to do this. Many industries need this tool for good results. Pharmaceuticals, food, cosmetics, and space research all use it.

Companies use the mixer to make particles smaller. This helps make products better.

The mixer can do many jobs, like mixing and dissolving.

It works faster than other mixers and uses less energy.

| Benefit | Description |

|---|---|

| Quality | Makes sure mixtures are even and high quality |

| Efficiency | Cuts down mixing time and saves energy |

| Versatility | Works with many products and different jobs |

Lots of labs pick this mixer because it gives steady results. It is great for making small batches again and again.

FAQ

What is the main purpose of a lab emulsifying mixer?

A lab emulsifying mixer creates stable mixtures from liquids that do not blend. It helps make creams, lotions, and medicines smooth and even.

How does a lab emulsifying mixer prevent air bubbles?

The vacuum system removes air from the mixing chamber. This keeps the mixture free of bubbles and helps products stay smooth.

Can a lab emulsifying mixer handle both thick and thin materials?

Yes. The mixer uses adjustable speed and different mixing heads. It can process thin liquids and thick creams with equal efficiency.

Why do industries prefer high-shear mixing?

High-shear mixing breaks large droplets into tiny ones. This process makes mixtures more stable and improves product quality.

Is cleaning a lab emulsifying mixer difficult?

Most mixers have built-in cleaning systems like CIP (Clean-In-Place). These systems make cleaning fast and easy, saving time for users.