Small-Scale Filling Machines You Should Consider in 2025

Are you searching for the best Filling Machines for your small business in 2025? Take a look at these top choices:

LTB Semi-Automatic Liquid Filler

XYZ Modular Filling Machine

ABC Compact Powder Filler

Manual Tabletop Filler

The right equipment can help you work faster. It can also help you use less labor. You can make your process quicker and easier. Semi-automatic and modular designs are now very popular. They are great for small-scale producers. Pick the best machine for your needs. You will see your business grow.

Key Takeaways

Pick a filling machine that matches your product and how much you make each day. This will help you save time and help your business grow. Semi-automatic and modular machines are fast and flexible. They are easy to upgrade as your business gets bigger. Manual tabletop fillers are good for small batches and low costs. They are a smart choice for people just starting out. Find machines that are simple to use, clean, and take care of. This will help you avoid delays and keep things running well. Make sure to check the warranty, if parts are easy to get, and if the supplier can help you. This will protect your money and help you when you need it.

Top Filling Machines 2025

Recommended Models

You want the best tools for your business. Here are the top Filling Machines you should check out in 2025:

LTB Semi-Automatic Liquid Filler

This machine works well for small beverage companies, cosmetics, and even cleaning products. You can fill bottles quickly and with less mess.XYZ Modular Filling Machine

If you need flexibility, this model stands out. You can add or remove parts to fit your production needs. It handles liquids, powders, and even thicker products.ABC Compact Powder Filler

This one is perfect for supplements, spices, or baking mixes. It fits on a small table and does not take up much space.Manual Tabletop Filler

If you are just starting out, this simple machine helps you fill jars or bottles by hand. It is easy to use and clean.

Tip: Think about your product type and how much you want to fill each day. The right machine can save you time and money.

Why These Machines Lead

These Filling Machines lead the market for a few reasons. First, they help you work faster and with less effort. You can fill more products in less time. Second, they are easy to use. You do not need special training to get started. Third, many models now offer modular designs. You can upgrade or change parts as your business grows. This means you do not have to buy a new machine every year.

You also get better accuracy. Your products look more professional. Customers notice when you use good equipment. In 2025, small businesses need tools that grow with them. These machines give you that edge.

Comparison Table

Key Specs Overview

You want to see how these filling machines stack up. Here’s a quick table that shows the main specs for each model. This makes it easy for you to compare and pick the right one.

| Model | Type | Filling Range | Speed (units/hr) | Size | Automation Level |

|---|---|---|---|---|---|

| LTB Semi-Automatic Liquid Filler | Liquid | 10ml – 1000ml | 600 – 1200 | Medium Countertop | Semi-Automatic |

| XYZ Modular Filling Machine | Multi (Liquid, Powder, Paste) | 5ml – 2000ml | 500 – 1500 | Modular/Custom | Semi-Automatic |

| ABC Compact Powder Filler | Powder | 1g – 500g | 400 – 900 | Small Tabletop | Semi-Automatic |

| Manual Tabletop Filler | Liquid/Paste | 10ml – 500ml | 100 – 300 | Small Tabletop | Manual |

Note: Speed and filling range can change based on your product and container size. Always check with the supplier for exact specs.

Application Suitability

Let’s match each machine to the best use case. You want to pick the one that fits your business.

LTB Semi-Automatic Liquid Filler

You fill drinks, oils, or cleaning liquids. This machine gives you speed and clean fills.XYZ Modular Filling Machine

You need flexibility. You switch between liquids, powders, or pastes. This model grows with your business.ABC Compact Powder Filler

You pack spices, supplements, or baking mixes. You want a small machine that fits anywhere.Manual Tabletop Filler

You start small. You fill jars or bottles by hand. You want something simple and easy.

Tip: Think about your product and how much you want to fill each day. The right machine helps you save time and grow faster.

You can see which machine matches your needs. If you want to scale up, look for semi-automatic or modular options. If you want something basic, manual models work well. Choose the one that fits your goals for 2025.

Types of Filling Machines

Liquid Filling Machines

Many small businesses use liquid filling machines. These machines fill bottles or jars with liquids. You can fill sauces, oils, lotions, or cleaning products. They work for thin and thick liquids like syrups. Food, beverage, cosmetic, and chemical companies use them every day.

Here’s a quick look at where you might use a liquid filling machine:

| Industry / Application | Typical Products Filled |

|---|---|

| Food and Beverage | Sauces, syrups, dressings, soups, oils |

| Pharmaceuticals | Medicines, lab reagents |

| Cosmetics and Personal Care | Shampoo, lotions, hand sanitizers |

| Chemicals | Various chemical liquids |

If you want to fill bottles fast and keep things tidy, a liquid filling machine is a smart pick.

Powder Filling Machines

Powder filling machines are best for things like spices or protein powders. You can use them for sticky or loose powders. These machines help you avoid messes and keep the weight right. Many small food, supplement, and chemical businesses use them to pack products.

Paste Filling Machines

Paste filling machines are for thick products. You can fill jars or tubes with peanut butter, creams, gels, or sauces. These machines handle sticky or chunky items that liquid fillers cannot. They are used in food, cosmetics, and pharmaceutical businesses.

Semi-Automatic vs. Manual

You can pick semi-automatic or manual filling machines. Manual machines are good for small batches or low costs. You fill by hand with these. Semi-automatic machines fill faster and need less effort. You press a button and the machine fills for you. Many small businesses start with manual machines and switch to semi-automatic later.

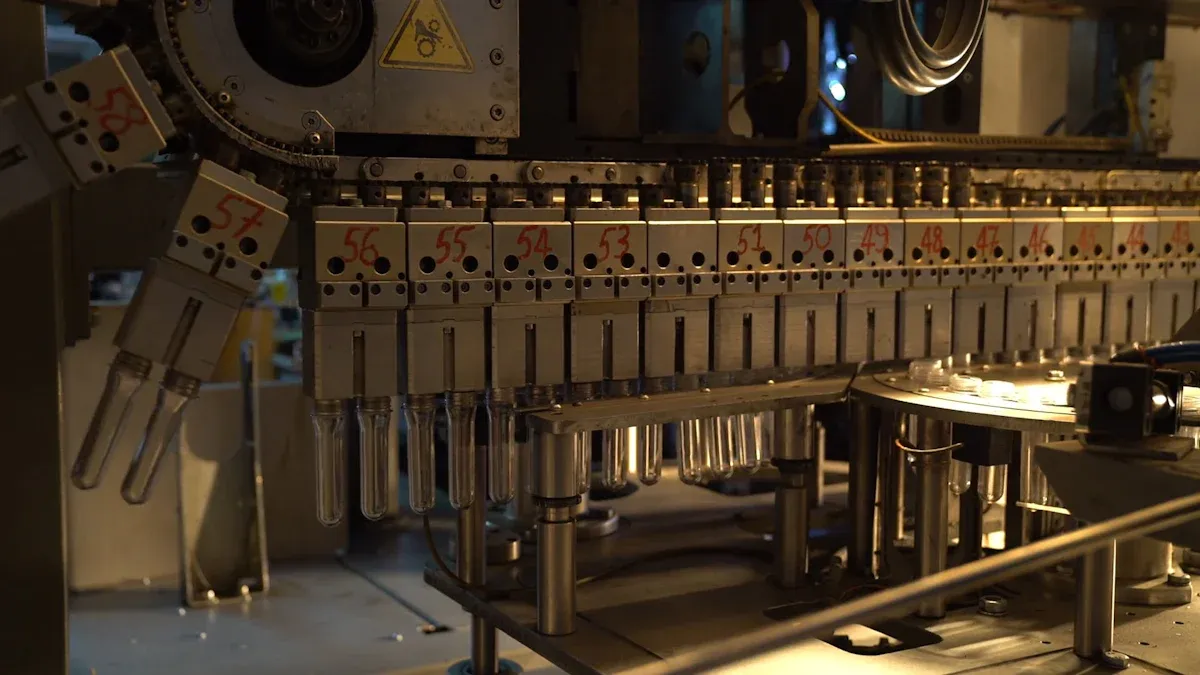

Modular Systems

Modular filling machines are very popular in 2025. You can add or take away parts to fit your needs. If you want to fill both liquids and powders, you can change modules. This saves money and space. Modular systems help your business grow without buying a new machine each time.

Many small producers now pick modular and semi-automatic filling machines. You get speed, flexibility, and room to grow in one machine.

Reviews of Top Picks

LTB Semi-Automatic Liquid Filler

You want a machine that makes your job easier. The LTB Semi-Automatic Liquid Filler does just that. You can fill bottles with drinks, oils, or cleaning liquids. The controls are simple. You press a button, and the machine fills each bottle with the right amount. You get clean fills every time. The design fits on most countertops, so you save space.

Features:

Adjustable fill volume

Fast filling speed

Easy-to-clean parts

Pros:

Quick setup

Reliable accuracy

Fits many bottle sizes

Cons:

Works best for liquids only

Best Use:

You run a small beverage, cosmetic, or cleaning product business. You want to fill bottles fast and keep things tidy.

If you want to boost your daily output and keep things simple, this machine is a smart choice.

XYZ Modular Filling Machine

You need flexibility. The XYZ Modular Filling Machine gives you that and more. You can switch between liquids, powders, and pastes. The modular design lets you add or remove parts. You can upgrade as your business grows. The machine uses smart sensors and control systems. You get real-time monitoring and easy adjustments. You can even check the machine from your phone.

Why does this machine stand out in 2025?

You can customize fill volumes and speeds.

The machine uses less energy and supports recycled materials.

Smart technology helps with remote monitoring and predictive maintenance.

You get advanced automation for better efficiency.

Pros:

Handles many product types

Scalable for future growth

Eco-friendly and energy efficient

Cons:

Higher initial investment

Best Use:

You want a machine that grows with your business. You fill different products and need to change settings often.

If you want a future-proof solution, this modular system gives you control, flexibility, and sustainability.

ABC Compact Powder Filler

You pack powders like spices, supplements, or baking mixes. The ABC Compact Powder Filler fits right on your table. You get accurate fills with every scoop. The controls are easy to use. You can adjust the fill weight for each batch. The machine does not take up much space, so you can use it in a small room.

Features:

Precise weight control

Compact design

Simple operation

Pros:

Saves space

Easy to clean

Consistent fills

Cons:

Best for powders only

Best Use:

You run a small food or supplement business. You need a reliable machine for powder products.

If you want to keep your workspace neat and fill powders quickly, this machine is a great pick.

Manual Tabletop Filler

You are just starting out. The Manual Tabletop Filler helps you fill bottles or jars by hand. You control each fill. The machine is light and easy to move. You can clean it in minutes. You do not need special training to use it.

Features:

Hand-operated lever

Adjustable fill size

Lightweight build

Pros:

Low cost

Simple to use

Portable

Cons:

Slower than automatic models

Best Use:

You fill small batches. You want a basic machine that gets the job done.

If you want to start small and keep costs low, this filler is a solid choice.

Choosing the Right Filling Machine

Assessing Production Needs

Start by looking at how much you want to fill each day. Count the number of bottles, jars, or containers you need to finish in one shift. If you plan to grow your business, think about how much more you might need to fill in the next year. Write down your daily and weekly targets. This step helps you pick a machine that keeps up with your orders and does not slow you down.

Matching Machine to Product

Next, match the machine to your product. Are you filling liquids, powders, or thick pastes? Some machines work best for thin liquids like juice or oil. Others handle powders or chunky sauces. Make sure the machine you choose fits your product type and container size. If you plan to offer new products soon, look for a model that can handle more than one type.

Budget and Scalability

Money matters when you pick a filling machine. Here’s what you can expect in 2025:

Entry-level tabletop models start at a few hundred dollars. These are great for small batches or new businesses.

Advanced machines with more filling heads and automation can cost tens of thousands of dollars. These boost speed and handle bigger jobs.

Machines with more automation and filling heads cost more up front and may need more maintenance.

The price also depends on the technology, container size, materials, and extra features.

Think about what you need now and what you might need later. If you want to grow, choose a machine that lets you add more features or speed up production.

Ease of Use and Maintenance

Pick a machine that you and your team can use without trouble. Simple controls and easy cleaning save time every day. Look for machines with clear instructions and quick-change parts. Good after-sales support is important, too. In 2025, many suppliers offer help with setup, training, and repairs. This support keeps your business running smoothly and helps you avoid long downtimes.

️ Tip: A machine that is easy to use and maintain will save you time and money in the long run.

Buying Considerations 2025

Technology Trends

You want to stay ahead in 2025. Filling Machines now come with smart features. Many models use touch screens and sensors. You can set fill levels with just a tap. Some machines connect to your phone. You get alerts if something needs attention. Modular designs let you add new parts when your business grows. Automation helps you fill more bottles with less effort. You save time and reduce mistakes.

Tip: Look for machines with easy upgrades. You can start small and add more features later.

User-Friendliness

You need a machine that anyone can use. Simple controls make training easy. Clear buttons and screens help you avoid confusion. Quick-change parts let you switch between products fast. You do not want to spend hours learning how to use your machine. Choose a model with a clean design and easy instructions.

Easy-to-read displays

Simple cleaning steps

Fast setup

Maintenance and Support

You want your Filling Machines to run smoothly. Regular cleaning keeps them working well. Pick a machine with parts you can remove and wash quickly. Good suppliers offer support when you need help. You can call or chat with experts if something goes wrong. Fast service means less downtime for your business.

| Support Feature | Why It Matters |

|---|---|

| Quick cleaning | Saves you time |

| Expert help | Solves problems fast |

| Spare parts supply | Keeps you running |

️ Note: Ask suppliers about after-sales service. Good support makes a big difference.

Warranty and Parts

You want peace of mind. Check the warranty before you buy. A strong warranty protects your investment. Ask about spare parts. You need easy access to replacements. Reliable suppliers keep parts in stock. You do not want to wait weeks for repairs. Make sure you know what is covered and how to get help.

Warranty length

Parts availability

Supplier reputation

If you follow these tips, you will find a Filling Machine that fits your needs and helps your business grow in 2025.

You have great options with these Filling Machines for 2025. Each one helps you work faster, cut waste, and keep your products consistent. When you choose scalable and efficient equipment, you get better accuracy, less downtime, and more flexibility for new products. These machines also help you meet safety and quality rules. Think about your goals and pick the model that fits your plans. Want to see them in action? Reach out to suppliers or ask for a demo today.

FAQ

What products can you fill with these machines?

You can fill liquids, powders, and pastes. Drinks, sauces, spices, supplements, and creams all work well. Just pick the right machine for your product type.

How much space do you need for a filling machine?

Most small-scale machines fit on a countertop or table. You need a clean, flat area. Some modular models need a bit more room if you add extra parts.

Can you upgrade your machine as your business grows?

Yes! Many semi-automatic and modular machines let you add new features or increase speed. You can start small and upgrade later when you need more capacity.

How do you clean and maintain a filling machine?

You remove the main parts and wash them with warm water. Some machines have quick-release features for easy cleaning. Regular cleaning keeps your machine running smoothly.