Practical Tips for Getting The Best From Your Lab-Scale Emulsifier

Pick a lab-scale emulsifier that fits your lab’s needs, like one with speed you can change and easy digital buttons.

Check the emulsifier before you use it each time to make sure droplet size stays the same and the mix is steady.

Use the drag-reducing liquid gating interfacial system to save energy and keep the temperature even, which helps protect ingredients that are sensitive.

Clean the lab equipment after every batch so it does not get dirty and keeps working well.

Write down all the settings and results for each time you make an emulsion so you can do it the same way again.

Key Takeaways

Pick a lab-scale emulsifier that fits your sample size. Make sure it meets your speed needs. Check if it works with your materials. This helps you get good, even emulsions.

Set up your equipment with care. Use standard tubes and steps. This helps you get the same results each time. It also helps you control droplet size.

Watch process settings like speed and time. Pay attention to surfactant ratios. This helps you make smaller droplets. It also makes your emulsions more stable.

Clean your emulsifier after each use. Take care of it often. This stops breakdowns and saves money. It helps your machine work well.

Write down all your settings and results. This helps you do well again. You can find problems early. You can make your emulsification better over time.

Preparation

Choosing a Lab-Scale Emulsifier

Picking the right lab-scale emulsifier helps scientists get good results. They need to match the mixer size to how much sample they have. The thickness of the liquid tells them what rotor speed and impeller size to use. Horsepower and speed should fit the product’s needs. Temperature control, like heating or cooling jackets, keeps sensitive ingredients safe. The lab must have enough space for the equipment to work safely. Stainless steel machines do not rust and are easy to keep clean. Some jobs need vacuum systems, hydraulic lifts, or motors that will not spark.

Tip: Always check if the materials work together. Stainless steel 316L is good for corrosive samples. PTFE coatings help with sticky products.

| Criteria | Explanation |

|---|---|

| Shear Force Requirements | Finer emulsions like nanoemulsions need higher RPM than coarse dispersions. |

| Material Compatibility | Use stainless steel 316L for corrosive materials; PTFE coatings for sticky products. |

| Scalability | Make sure lab results can be scaled up to bigger batches. |

| Regulatory Compliance | Following GMP, FDA, and ISO rules is important for medicine and cosmetics. |

A lab-scale emulsifier with vacuum lets you control the process better. This makes the product more even and high quality. It also helps save resources and recover vapor, making the lab work better.

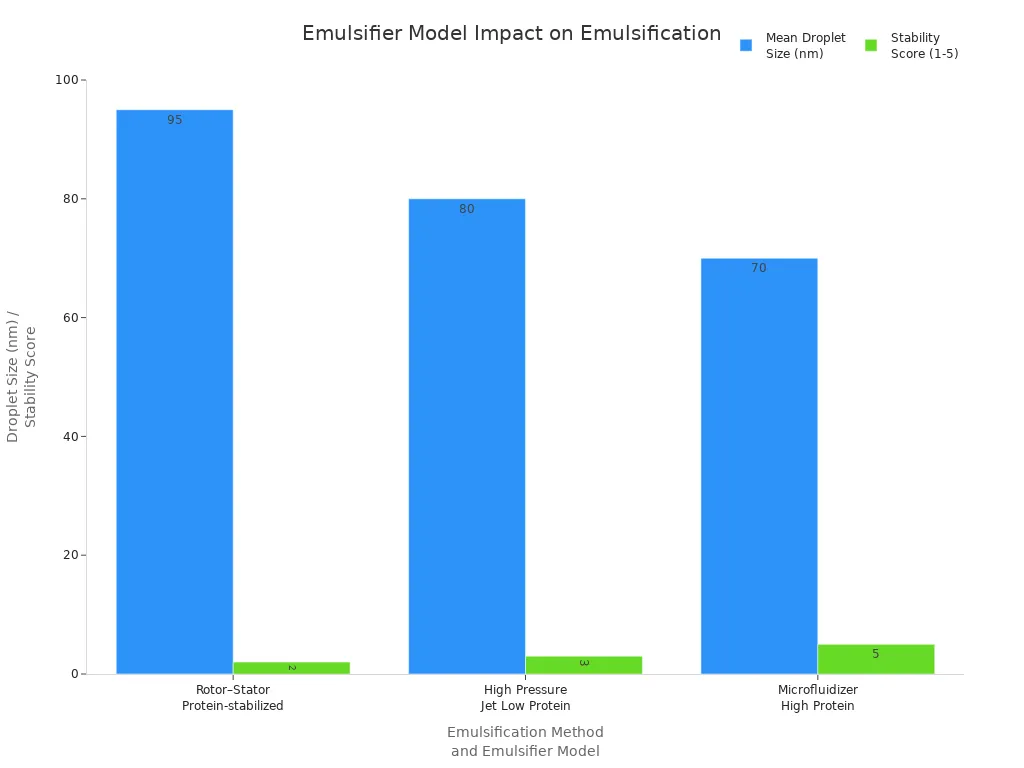

The type of emulsifier and method changes droplet size, stability, and energy use. For example, a mixer with a very fast rotar/stator system makes smaller droplets and more stable emulsions. The chart below shows how different methods and models compare:

Setup and Calibration

Setting up and calibrating lab equipment the right way gives steady mixing and good emulsions. Scientists use the same glass tubes and caps to keep tests fair. They mix water solutions with n-heptane, then shake them fast for two minutes. After mixing, they let the emulsion sit for ten minutes before checking results.

Use 4 mL screw cap glass tubes (10 × 75 mm, ND10 caps with PTFE septum).

Make the test emulsifier solution and add 1 mL of n-heptane.

Shake the mixture fast for two minutes.

Stand the tubes up and let the emulsion settle for ten minutes.

Add more test product until the organic phase is fully emulsified.

One emulsification unit is the smallest amount needed for a full emulsion.

Find emulsifying activity by dividing 1 U by the smallest volume (mL).

Test the method with different surfactants and detergents.

Keep tube size, shape, and hydrophobic phase the same for repeatable results.

| Factor | Effect on Emulsion Quality and Consistency | Explanation |

|---|---|---|

| Emulsifier Concentration | Makes droplets smaller, improves stability | More emulsifier means smaller droplets and better stability. |

| Mixer Geometry Optimization | Helps mixing and emulsion quality | Good geometry mixes fluids and spreads phases better. |

| Calibration and Setup Precision | Needed for droplet size and phase control | Careful setup gives the same results each time. |

A mixer with a very fast rotar/stator system gives better control over droplet size and phase. Scientists should watch process settings and change equipment as needed to keep batches the same.

Process Optimization

Ingredient Selection

Picking the right ingredients is very important. Scientists choose oils, water, and surfactants that work well together. They check if these mix easily and stay mixed for a long time. Some surfactants help keep droplets small. This stops them from joining together. The best surfactant blend makes the emulsion last longer and look nicer.

Tip: Using the right amount of each surfactant helps control droplet size. It also makes the emulsion more stable. For example, changing the SDBS to Span80 ratio changes how well the emulsion stays together.

A lab scale inline mixer helps mix powders and liquids fast. This tool makes a good blend, which is important for making new products. Scientists use small mixers to test new ideas before making bigger batches.

Process Parameters for Emulsifier

Controlling the process is very important for good mixing. Scientists change the speed, time, and temperature when making an emulsion. Each thing changes droplet size and how stable the emulsion is.

| Process Parameter | Effect on Droplet Size Distribution | Effect on Emulsion Stability (TSI) | Notes and Theoretical Explanation |

|---|---|---|---|

| Shear Speed | Higher speed makes smaller droplets | Higher speed gives better stability | This is the most important factor; range studied: 1000 to 16000 rpm |

| Shear Time | Longer time makes droplets a bit smaller | Longer time helps stability but not as much as speed | Range studied: 10 to 15 minutes |

| Mass Ratio of SDBS to Span80 | Changing the ratio changes droplet size | The best ratio gives better stability | Ratio range: 0.45 to 1.48; surfactant mix changes how the surface acts |

| Droplet Size (D50) | Smaller droplets with best settings | Smaller droplets mean better stability | Small droplets are harder to join together and move slower (DLVO theory and Stokes-Richardson-Zaki model) |

| Destabilization Mechanisms | N/A | Gravity and droplets joining cause problems | Droplets become unstable in a certain way (first-order kinetics with R² > 0.99) |

The homogenizer must run at the right speed to break up droplets. This keeps them from joining together. Faster speeds make smaller droplets and better stability. Mixing longer helps too, but not as much as speed. The best results come from using the right speed and time.

Scientists use special computer tools like CFD and population balance models. These tools help guess how droplets will act. They save time and cut down on tests. They also help make emulsions that people want to buy.

Batch Size and Scaling

Making bigger batches from lab tests needs careful planning. Scientists must keep mixing and flow the same to get good results. They use special numbers like Reynolds, Froude, and Weber to compare mixing at different sizes. These numbers help match what happens in the lab to bigger machines.

Careful planning helps stop problems and keeps things working well.

Watching the process with good controls keeps the product the same.

Picking equipment that can grow bigger keeps things working right.

Good cooling or heating protects the product.

Better mixing and mass transfer make more and better product.

Checking during the process keeps the product clean.

Training workers and talking as a team helps everyone do well.

Trying pilot tests and using computer tools helps find the best way to scale up.

The homogenizer is very important when making bigger batches. It must work well for both small and big amounts. Scientists use tests and computer models to see if the process works at all sizes. This helps keep mixing good and the product high quality.

Note: Labs often use both test data and CFD computer models to check and improve emulsification. This makes sure that results from small mixers can be trusted when making bigger batches.

By following these steps, scientists can make good emulsions every time. They can also make sure their research leads to products that work well in real life.

Troubleshooting and Maintenance

Laboratory Homogenizer Emulsifier Issues

Many scientists have trouble with laboratory homogenizer emulsifiers. Sometimes, the emulsion does not stay mixed. Droplet size can change each time. The machine might get too hot and hurt sensitive ingredients. If the homogenizer is too fast or slow, mixing does not work well. Filters can get blocked or parts can get dirty and slow things down.

Common problems are:

Emulsions that break apart fast.

Droplets that are too big or not the same size.

The machine gets too hot while mixing.

Filters get blocked or dirty.

The machine makes loud noises or shakes.

Tip: Scientists should check the laboratory homogenizer emulsifier before using it. They need to look for leaks, odd noises, or changes in speed. Checking early helps stop bigger problems later.

Cleaning and Upkeep

Cleaning and upkeep help the laboratory homogenizer emulsifier work well. Scientists clean all parts after every batch. They use brushes and safe cleaners. Filters should be checked and changed often. The team looks at seals and moving parts for damage.

Best ways to keep things working:

Clean the mixing chamber and blades after each use.

Check and change filters to stop blockages.

Look at seals and moving parts for damage.

Watch coolant levels and how strong it is.

Write down when you clean and fix things.

A good plan for upkeep saves the laboratory money and time. The table below shows how these steps help stop problems and save money:

| Maintenance/Troubleshooting Practice | Impact on Downtime and Cost Savings |

|---|---|

| Regular lab analysis of fluids | Finding thick oil, bacteria, or bad coolant early lets you fix things before the machine breaks. This keeps the machine working and saves money. |

| Maintaining chiller and filtration systems | Keeps the machine cool and clean, so it does not break down. This means fewer repairs and lower costs. |

| Monitoring viscosity and coolant concentration | Helps you know when to change fluids, which makes the machine last longer and saves money. |

| Maintaining proper coolant concentration (around 7%) | Stops rust, bacteria, bad cooling, blocked filters, foam, and skin problems. This keeps the machine working well and saves on repairs. |

| Using filtration to remove solid particles | Stops fluids from getting old too fast and keeps the machine safe. This means fewer repairs and less downtime. |

Note: Scientists who do these steps keep their laboratory homogenizer emulsifier working well. They do not have to pay for big repairs and get better results every time they make an emulsion.

Consistency and Documentation

Standardizing Emulsifier Procedures

Standard operating procedures help labs get the same results. These steps control mixing speed, time, temperature, and deaeration. Scientists follow the same steps for every batch. This helps make emulsions that look and act the same.

Using the same mixing speed and time lowers mistakes.

Deaeration takes out air and stops problems like instability and germs.

Mixing well and keeping heat steady stops creaming or sedimentation.

Machines like the FagronLab™ PM140 mix, melt, and deaerate in one step. This makes the process faster and easier.

Following the same steps helps labs avoid mistakes and keep quality high. It also helps new team members learn faster.

Here is a table that shows how standard steps help:

| Procedure Step | Benefit |

|---|---|

| Fixed mixing speed | Same droplet size every batch |

| Controlled temperature | Protects sensitive ingredients |

| Deaeration | Prevents instability |

| Set mixing time | Reduces batch-to-batch changes |

Record-Keeping for Homogenizer

Good record-keeping helps labs work better. Scientists write down every setting and result for each batch. This helps them repeat good results and find mistakes.

Digital controls and automatic data collection make records more accurate. Systems with AI and computer vision, like the Opentrons OT-2, check liquid levels and pipette tips as you work. These tools lower human mistakes and help keep batches the same. Fast image checks help labs spot problems quickly, even when busy.

Tip: Use digital logs to track every change. This helps compare batches and fix problems fast.

Labs that use digital records and standard steps make better emulsions. They save time, make fewer mistakes, and keep products safe and stable.

Scientists who use helpful tips with a lab-scale emulsifier get better results.

Using the same ways to test, like checking surface tension and stability indexes, helps compare how well things work.

Keeping the temperature and ionic strength steady makes emulsions last longer.

Picking ingredients with the right shape helps mixing and keeps results good for a long time.

Doing tests and using computer tools together helps find the best settings faster.

Using these steps every time makes high-quality emulsions and saves time in the lab.

FAQ

What is the best way to clean a lab-scale emulsifier?

Scientists should take apart the machine and wash each part with warm water and mild soap. They should use a soft brush for hard-to-reach spots. Drying all parts before reassembly helps prevent rust.

How can someone tell if an emulsion is stable?

They can check if the emulsion stays mixed after sitting for a few hours. A stable emulsion does not separate into layers. Scientists often use a stability index or measure droplet size over time.

Why does droplet size matter in emulsions?

Droplet size affects how long the emulsion lasts and how it looks. Smaller droplets make the emulsion more stable and smooth. Scientists use special tools to measure droplet size for quality control.

What should a scientist do if the emulsifier overheats?

Turn off the machine right away. Let it cool before checking coolant levels and airflow. Clean any blocked filters. If the problem continues, contact the equipment supplier for help.