INDUSTRIES

Introduction to the Enhanced Production Efficiency of Dual Dispersion in Customized Toothpaste Machines

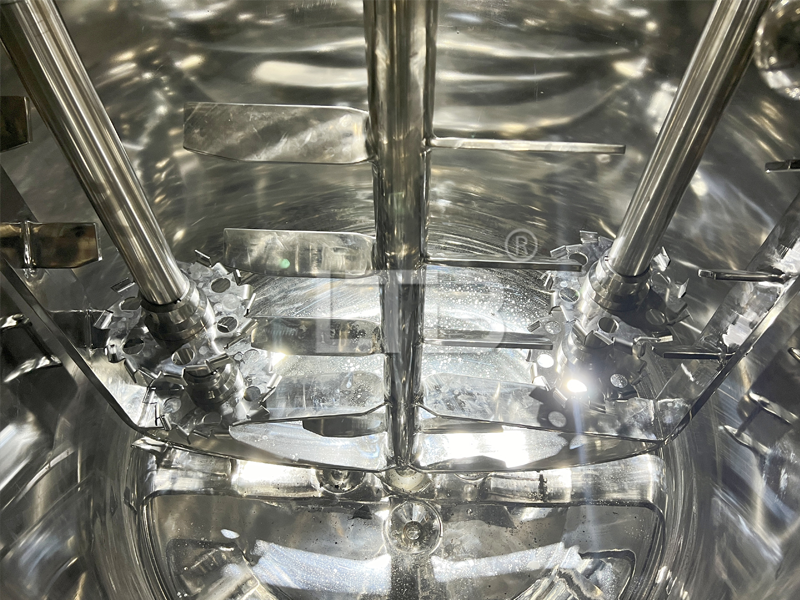

In the highly competitive field of toothpaste manufacturing, continuous innovation and improvement in production equipment are crucial. The customized toothpaste machine with dual dispersion technology represents a significant advancement that has revolutionized the production process and outcomes.

The dual dispersion system incorporated in these machines is designed to address the challenges associated with the complex formulation of toothpaste. Toothpaste typically consists of a variety of ingredients, including abrasive agents, fluoride compounds, flavorings, and binders, which have different physical and chemical properties. The traditional mixing methods often face difficulties in ensuring a uniform and stable dispersion of these components.

The implementation of dual dispersion in customized toothpaste machines has several notable production effects. Firstly, it significantly improves the homogeneity of the final product. A more homogeneous toothpaste not only offers consistent quality in terms of texture and flavor but also ensures that each application delivers the same level of dental protection. Secondly, it enhances the stability of the formulation. By reducing the size of particles and achieving a more uniform dispersion, the risk of ingredient separation or settling during storage and transportation is minimized. This leads to a longer shelf life and better product integrity. Thirdly, the production efficiency is increased. The dual dispersion process reduces the overall mixing time required compared to traditional methods. Faster production cycles mean higher output rates, allowing manufacturers to meet market demands more effectively and potentially reduce production costs.

In conclusion, the customized toothpaste machine with dual dispersion technology is a remarkable innovation that has transformed the toothpaste manufacturing process. Its ability to precisely and effectively disperse the various ingredients of toothpaste not only improves product quality and stability but also boosts production efficiency, giving manufacturers a competitive edge in the market and enabling them to provide consumers with superior dental care products.

Market Analysis and Customization in the Cosmetics and Skincare Industry

Market Demand in the Cosmetics and Skincare Industry

The cosmetics and skincare industry has experienced remarkable growth in recent years. Consumers' increasing awareness of personal appearance and skin health has led to a surge in demand for a wide variety of cosmetic and skincare products. This includes facial creams, serums, makeup items such as foundations and lipsticks, and body care products like lotions and scrubs.

Moreover, the trend towards natural and organic ingredients has become prominent. Consumers are more inclined to choose products that are free from harmful chemicals and are environmentally friendly. Additionally, the demand for anti-aging, whitening, and moisturizing products remains consistently high, driven by the desire to maintain youthful and healthy skin. The market also witnesses seasonal fluctuations, with certain products being more popular during specific times of the year. For example, sunscreen and lightweight skincare products are in greater demand during the summer months, while heavier moisturizers and lip balms are favored in winter.

What Machines Are Needed in the Production Process?

What Customizations Can We Offer Based on Your Requirements?

Market Demand and Customized Solutions in the Daily Chemical Industry

Market Demand in the Daily Chemical Industry

The daily chemical industry encompasses a broad range of products that are essential for daily life, including personal care products such as soaps, shampoos, and toothpaste, as well as household cleaning products like detergents and disinfectants.

In recent years, consumers have shown a growing preference for products that are not only effective but also environmentally friendly and sustainable. There is an increasing demand for natural and organic ingredients in personal care items, driven by concerns about skin health and environmental impact. For example, sulfate-free shampoos and paraben-free cosmetics have gained significant popularity. In the household cleaning segment, consumers are seeking products that are biodegradable and have reduced toxicity.

Moreover, the market is highly influenced by trends and seasons. For instance, during the flu season, there is a spike in the demand for antibacterial soaps and disinfectants. In summer, sunscreen and mosquito repellent products are in high demand. Additionally, the rise of e-commerce has changed the purchasing patterns, with consumers expecting convenient packaging and fast delivery.

What Machines Are Needed in the Production Process?

What Customizations Can We Offer Based on Your Requirements?

Market Demand and Customized Solutions in the Ointment Industry

Market Demand in the Ointment Industry

The ointment industry serves diverse medical and cosmetic purposes. In the medical field, there is a continuous demand for topical ointments for treating skin diseases, relieving pain, and promoting wound healing. The aging population and the increasing prevalence of skin disorders have contributed to the growth of this segment. Consumers are also seeking natural and herbal-based ointments with fewer side effects. In the cosmetic realm, ointments for skin moisturizing, anti-aging, and scar reduction are popular. Moreover, the demand for ointments with convenient packaging and long shelf life is on the rise, especially with the growth of e-commerce and global trade.

What Machines Are Needed in the Production Process?

What Customizations Can We Offer Based on Your Requirements?

Market Demand and Customized Solutions in the Powder Industry

Market Demand in the Powder Industry

The powder industry plays a crucial role in various sectors. In the food and beverage industry, powdered ingredients like flour, cocoa powder, and powdered milk are essential for manufacturing a wide range of products. The pharmaceutical industry heavily relies on powdered drugs and excipients for tablet and capsule production. In the cosmetics and personal care sector, powder cosmetics such as face powders and blushers are in high demand. Additionally, the chemical and construction industries use powders for coatings, fillers, and additives.

Consumers are increasingly concerned about the quality and purity of powders. For food and pharmaceutical powders, strict quality and safety standards must be met. There is also a growing trend towards natural and organic powders. In the industrial sector, the demand for high-performance powders with specific properties like particle size distribution, flowability, and chemical stability is on the rise.

What Machines Are Needed in the Production Process?

What Customizations Can We Offer Based on Your Requirements?

Market Demand and Customized Solutions in the Perfume Industry

Market Demand in the Perfume Industry

The perfume industry has witnessed consistent growth and holds a significant position in the global market. There is a strong demand for a diverse range of perfumes to cater to different consumer preferences and occasions. Consumers seek unique and long-lasting fragrances that can express their individuality and enhance their personal charm.

In recent years, the trend of niche and artisanal perfumes has gained momentum. These perfumes often feature rare and exotic ingredients, appealing to consumers who desire exclusivity. Additionally, there is an increasing demand for sustainable and eco-friendly perfumes. Consumers are more conscious about the sourcing of ingredients and the environmental impact of perfume production. The market also experiences seasonal fluctuations, with lighter and fresher fragrances being popular in spring and summer, while warmer and more intense scents are favored in fall and winter.

What Machines Are Needed in the Production Process?

What Customizations Can We Offer Based on Your Requirements?

Market Demand and Customized Solutions in the Sauce Industry

Market Demand in the Sauce Industry

The sauce industry has experienced robust growth due to the increasing diversity of global cuisines and consumers' desire for enhanced flavor experiences. There is a wide range of sauce types, including ketchup, mayonnaise, barbecue sauce, soy sauce, and various ethnic and specialty sauces.

Consumers today demand not only delicious flavors but also high-quality, natural, and preservative-free products. Health-conscious consumers look for sauces with reduced sodium, sugar, and artificial additives. Additionally, the demand for organic and gluten-free sauces is on the rise. The market also witnesses a trend of convenience, with single-serve packets and squeezable bottles becoming popular for on-the-go consumption. Moreover, the globalization of food culture has led to an increased demand for international sauce varieties, fueling innovation and the introduction of new flavor combinations.

What Machines Are Needed in the Production Process?

What Customizations Can We Offer Based on Your Requirements?