How To Select The Right Filling Machine for Your Production Needs

When you Choose Filling Machine, it’s essential to match the machine to your specific product and container. Additionally, consider your production goals carefully. The right filling machine enables you to work faster and with greater accuracy, ultimately saving you money. Advanced dosing chambers and microprocessor controls can enhance accuracy by up to 25%. Selecting the right filling machine can also reduce rejected batches by as much as 60%, cutting costs related to waste and error correction.

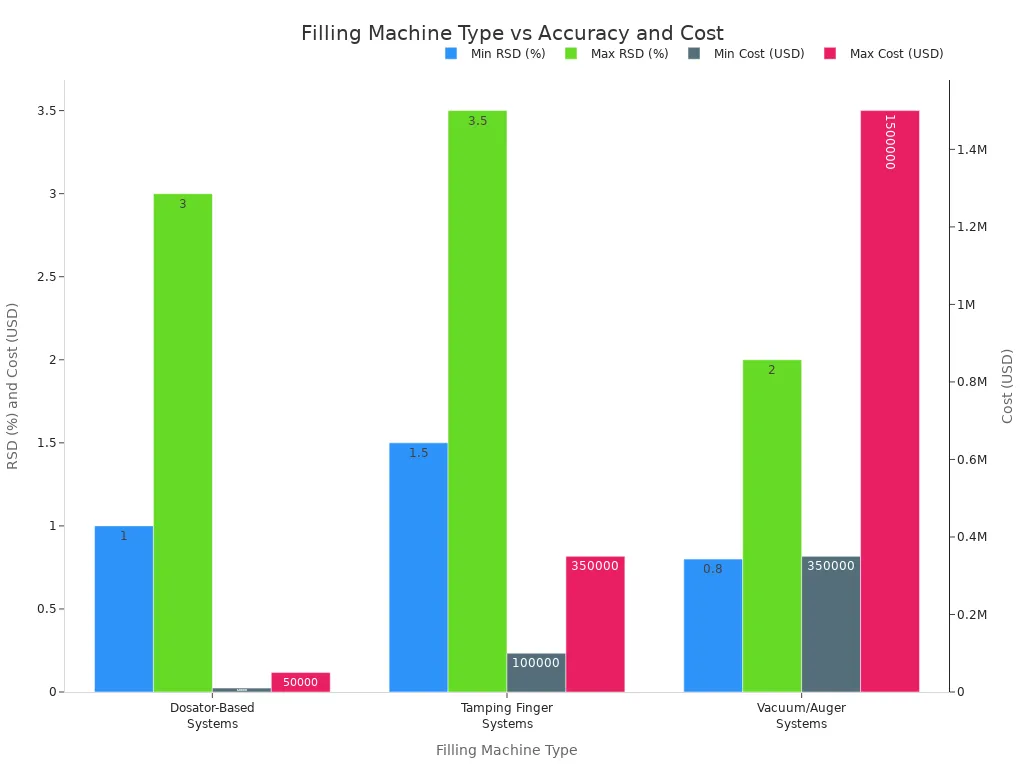

| Filling Machine Type | Relative Standard Deviation (RSD) | Production Capacity (capsules/hour) | Typical Cost Range (USD) | Accuracy Impact and Cost Implications |

|---|---|---|---|---|

| Dosator-Based Systems | 1-3% | Moderate | $10,000 - $50,000 | Accuracy improved by 15-20% |

| Tamping Finger Systems | 1.5-3.5% | Moderate to High | $100,000 - $350,000 | Deviation reduced by up to 30% |

| Vacuum/Auger Systems | 0.8-2% | High | $350,000 - $1,500,000+ | Accuracy improved by up to 25% |

Tip: When you Choose Filling Machine, carefully evaluate your production needs, product requirements, and desired output before making your decision.

Key Takeaways

Pick a filling machine that fits your product’s thickness. Make sure it also matches your container size. This helps filling go fast and stay accurate.

Think about how much you make now and later. Choose a machine that can handle more work as your business grows. This can help you save money over time.

Try your product and container with the machine before you buy it. This helps you avoid problems and keeps things running well.

Pick the right automation level for your needs. This helps balance speed and the number of workers. It makes your business work well now and in the future.

Find machines that are easy to clean and fix. Good support helps you have less downtime and makes the machine last longer.

Product and Container

Viscosity and Fill Accuracy

You should think about how thick or thin your product is. This is called viscosity. Water, juice, and oils are thin. Honey, creams, and gels are thick. If your product has small pieces, you need to think about how they move in the machine.

Thin liquids use gravity or overflow fillers. These machines let the product flow down into containers.

Thick products need piston or pump fillers. These machines push the product with more force.

Products with particulates need special nozzles or bigger valves. This stops clogs and helps fill each container evenly.

Tip: Always check how accurate you need to fill. If you fill medicine or cosmetics, you may need very exact amounts. Machines with advanced controls help you fill with high accuracy. This cuts waste and saves money.

Container Type

The kind of container you use matters too. You need to look at the size, shape, and material of your containers.

Size: Small bottles need machines for tiny openings. Big jugs or buckets need machines with bigger nozzles.

Shape: Round bottles are easy to fill. Odd shapes or narrow necks may need special nozzles or guides.

Material: Glass, plastic, and metal act differently. Some machines work better with certain materials.

| Container Feature | Machine Consideration |

|---|---|

| Small openings | Precision nozzles |

| Wide mouths | High-volume nozzles |

| Fragile material | Gentle handling mechanisms |

You should always test your product and container with the machine first. This helps you find problems early and keeps production running smoothly.

Production Volume

Output and Speed

You need a filling machine that matches your output goals. Small businesses or people testing new products fill only a few containers each hour. Big factories fill hundreds or thousands every minute. The machine you pick controls how fast you can work.

Here is a simple chart about production speeds:

| Machine Type | Production Speed | Labor Requirement | Scale Suitability |

|---|---|---|---|

| Manual | Slowest (fully manual operation) | Full manual labor | Small-scale, very low output |

| Semi-Automatic | Moderate (slower than automatic) | Manual loading and operation | Small to medium scale |

| Automatic | Fastest (hundreds to thousands per minute) | Minimal manual intervention | Large-scale, high volume |

Manual machines are the slowest. You must load and use them by hand. Semi-automatic machines are faster, but you still help with loading and starting. Automatic machines are the fastest. They fill many containers with little help from you. If you want your business to grow, pick a machine that can keep up.

Tip: Always think about how much you need to fill now and later. A slow machine can stop your business from growing.

Scalability

Your needs might change as your business grows. You may start small but need more output later. Scalability means your filling machine can do more work when you need it.

Pick a machine that lets you add more filling heads or faster parts.

Some machines let you switch from semi-automatic to automatic.

Look for machines that fit into bigger production lines if you want to expand.

If you plan for growth now, you save money and time later. You will not need a new machine right away when your business gets bigger. Scalability helps you stay ready for new chances.

Choose Filling Machine

Machine Types

You need to know the main machine types. Each type works best with certain products and containers. Here are some common types you will see:

Piston Fillers

Piston fillers use a piston to move product into a chamber. Then, the piston pushes it into the container. Use these for thick products like creams or sauces. They also work well with chunky products.Gravity Fillers

Gravity fillers let liquid flow down into containers. These are best for thin liquids like water or juice. They are simple to use and easy to clean.Overflow Fillers

Overflow fillers fill containers to the same level each time. Use these for clear bottles or when looks matter. They work with thin or medium liquids.Pump Fillers

Pump fillers use a pump to move product into containers. You can use these for many kinds of products, thin or thick. They handle foamy or sticky products well.Sachet Fillers

Sachet fillers fill and seal small pouches. You see these for single-serve items like ketchup or sugar. They are good for small, easy-to-carry packages.

Note: Always test your product with the machine first. This helps you avoid problems when you start production.

| Machine Type | Best For | Example Products |

|---|---|---|

| Piston | Thick, chunky, viscous | Honey, lotion, salsa |

| Gravity | Thin, free-flowing | Water, juice, vinegar |

| Overflow | Level fills, clear bottles | Shampoo, mouthwash |

| Pump | Wide range, foamy | Creams, gels, detergents |

| Sachet | Small pouches | Ketchup, sugar, coffee |

Automation Levels

You also need to think about automation. The right automation helps you reach your goals.

Manual Machines

Manual machines need you to do everything by hand. You load containers and start the fill yourself. These are best for small batches or when you want control. You spend more time on each container.Semi-Automatic Machines

Semi-automatic machines do some work for you. You may load containers, but the machine fills them. These are faster and more even than manual machines. They fit small or medium businesses.Automatic Machines

Automatic machines do almost all the work. You set up the machine, and it fills and caps containers. You get fast speed and need less help. These are best for big production lines.

| Automation Level | Labor Needed | Speed | Best For |

|---|---|---|---|

| Manual | High | Slowest | Small batches, startups |

| Semi-Automatic | Medium | Moderate | Growing businesses |

| Automatic | Low | Fastest | Large-scale production |

Tip: Match the automation level to your needs now and later. If you want to grow, pick a machine you can upgrade.

Always look at your product, container, and goals before you choose filling machine types and automation. The right choice saves time and cuts waste. It helps your business get ready to grow. If you need help, talk to a filling machine expert. They can help you find the best machine for you.

Maintenance and Support

Material Compatibility

You must make sure your filling machine works with your product and container. Some machines have stainless steel parts. These parts do not rust and can handle acids or salty things. Other machines have plastic or rubber seals. These seals can wear out fast if you use strong chemicals.

| Material Type | Machine Part Needed | Why It Matters |

|---|---|---|

| Acidic liquids | Stainless steel | Prevents corrosion |

| Alcohol-based | Special seals | Stops leaks and damage |

| Sticky products | Non-stick surfaces | Makes cleaning easier |

| Glass containers | Gentle handling parts | Avoids cracks or chips |

You should always ask your supplier if the machine parts match your materials. If you use the wrong parts, you might get leaks, rust, or broken containers. Testing your product with the machine helps you find problems early.

Tip: Pick machines that are easy to clean. This keeps your work safe and cuts down on stops.

Aftermarket Support

You need good help after you buy your filling machine. Good support helps you fix problems fast and keeps your machine working.

Find suppliers who have spare parts and quick repairs.

Ask if they train your team.

See if they offer phone or online help.

If you get regular check-ups, your machine will last longer. You will avoid big breakdowns and keep your work going.

Note: Good support means less worry for you. You can focus on making products, not fixing machines.

Keep a list of trusted people for service and parts. This helps you fix problems fast. Good support protects your machine and helps your business grow.

Budget and Longevity

Investment

You need to look at more than just the price tag when you choose a filling machine. The cheapest machine may not save you money in the long run. Think about what you get for your money. A good machine gives you reliable performance, fewer breakdowns, and less waste.

Here are some things to consider before you buy:

Initial Cost: This is the price you pay to buy the machine.

Operating Costs: These include electricity, cleaning, and labor.

Maintenance Costs: You may need to replace parts or pay for repairs.

Downtime Costs: If your machine stops working, you lose time and money.

| Cost Type | What to Watch For |

|---|---|

| Initial | Purchase price, installation |

| Operating | Power use, labor, cleaning |

| Maintenance | Spare parts, service visits |

| Downtime | Lost production, urgent repairs |

Tip: Always ask for a full cost breakdown from your supplier. This helps you plan your budget and avoid surprises.

Future Growth

You want your filling machine to last as your business grows. A machine that fits your needs today may not work for you tomorrow. Choose a machine that can handle more work if you need it.

Look for these features:

Upgradeable Parts: Some machines let you add more filling heads or faster motors.

Flexible Design: Machines that adjust to different container sizes or products help you launch new items.

Integration Ready: Pick a machine that connects with other equipment, like cappers or labelers.

️ Note: Planning for growth now saves you money later. You will not need to buy a new machine every time your business gets bigger.

Think about your goals for the next few years. If you expect to grow, invest in a machine that grows with you. This smart choice keeps your production running smoothly and supports your success.

When you pick a filling machine, think about your product. Also, look at your container and what you want to make. Check different machine types and how much work they do for you. Look at the help and support you can get. Make sure the machine fits what you need now and later. If you need help, ask an expert for advice. A good choice helps you work faster and waste less. Making a smart choice today can help your business grow.

FAQ

What is the best filling machine for thick products?

You should pick a piston or pump filler for thick stuff. These machines push thick liquids like honey or lotion into containers. They do not get clogged easily. Always try your product with the machine first.

How do I know if my machine fits my container size?

Check the nozzle size and see if it can change. Many machines have different nozzles for small bottles or big jugs. Ask your supplier for a chart that shows what fits.

Tip: Try your container with the machine before you buy.

Can I upgrade my filling machine later?

Many machines let you add upgrades. You can put on more filling heads or change to automatic controls. Look for machines that let you add new parts as your business grows.

| Upgrade Option | Benefit |

|---|---|

| Extra filling heads | Faster work |

| Automation kits | Less hand labor |

How often should I clean my filling machine?

Clean your machine after every time you use it. This keeps your products safe and stops clogs. Some machines have parts you can take off easily for cleaning.

Note: Cleaning often helps your machine last longer.