A detergent powder mixer gives three main benefits. It makes quality stay the same. It works faster. It saves money. Many detergent makers have problems. Powders can clump. Dust can form. Mixing can be uneven. High shear wet granulation mixers help powders move better. They also cut down on waste. There are different mixer types. Ribbon, double cone, and V-shaped mixers fit different jobs:

| Mixer Type | Key Features | Industrial Applications |

|---|---|---|

| Ribbon Mixer | Mixes well, uses spiral agitator | Detergent powder, flour, spices |

| Double Cone Mixer | Mixes dry powders and granules | Pharmaceuticals, food, chemicals |

| V-shaped Mixer | Blends powders and granules evenly | Industrial powders, tea, additives |

Mixers can be changed with special features. These include temperature control and different sizes. These benefits help makers fix common problems. They also make production better.

Key Takeaways

Detergent powder mixers help make every batch the same. They mix powders well and stop clumps and dust from forming.

Mixers make production faster and help factories work quicker. They let factories make more powder in less time and with less work.

Mixers help save money by needing fewer workers. They also cut down on waste and use energy in a smart way. Mixers made from strong stainless steel last longer.

These mixers are used in many types of businesses. They can be changed with things like automation and special blades to fit what is needed.

Picking the best mixer and getting expert help makes products better. It also helps companies save resources and do better in making products.

Consistent Mixing

Uniform Quality

A detergent powder mixer helps make every batch the same. Ribbon blenders, paddle mixers, and V shape mixers all mix powders in their own way. Ribbon blenders move powder along the middle and make it fall gently. Paddle mixers use angled paddles to lift and toss the powder. This helps the powder move around more. V shape mixers spin and make powder flow over the top. All these mixers blend ingredients well. Paddle mixers usually mix the best.

Tests show paddle mixers can mix very well, over 95%, in under 15 minutes. Scientists use special tools and samples to check if the mix is even. They also use computer tests to see how speed and fill level change mixing. When makers change these settings, they can make the powder more even.

Mixers are often made of stainless steel. This keeps the mixer from rusting and makes it easy to clean. Makers can mix big or small batches and still get good results. Some mixers have smart controls to watch speed and shaking. This helps keep mixing just right.

Less Waste

Good mixing stops clumps and uneven powder. The Pam Apex Mixer uses fast mixing and spreading. This breaks up lumps and spreads powder everywhere. When powder mixes well, clumps break and spread out. Makers waste less powder and throw away fewer batches.

Detergent powder mixers mix everything, so nothing is left out.

Even mixes mean less dust and fewer bad products.

Good mixing saves money and uses fewer resources.

Mixers that follow GMP rules and have clean designs help keep production safe. Makers know each batch will be good and waste will be low.

Efficiency Boost

Faster Production

A detergent powder mixer helps mix faster than by hand. Workers who mix by hand need many hours to finish. Machines like horizontal paddle mixers work much quicker. Continuous granulators also mix fast. The Bepex Turbulizer can mix and form particles almost right away. It mixes solids and liquids with settings for speed and time. This makes even, dust-free powder in less time.

| Process Type | Advantages for Speed | Challenges for Speed |

|---|---|---|

| Continuous Mixing | Powders move without stopping between batches | Needs careful checks for even mixing |

| Batch Mixing | Easy to measure and collect each batch | Takes longer, with breaks between batches |

Continuous mixing lets factories keep working without stopping. Batch mixing gives more control but is slower. Both ways are faster than mixing by hand.

Higher Output

Factories that use a detergent powder mixer make more powder. Ribbon mixers and agglomerators can handle lots of powder at once. These machines blend, sift, and pack powder in a steady way. The process uses less energy and less time.

| Aspect | Dry Mixing (Ribbon Mixers) | Agglomeration (Granulators) |

|---|---|---|

| Equipment Needed | Mixers, conveyors, sifters | Granulators, dryers, binder dispensers |

| Production Capacity | Medium to high, fits what is needed | Medium to large, good for big factories |

| Benefits | Saves time, uses less energy, even mix | Makes even granules, easy to handle |

Automation helps factories work even better. Touchscreens let workers set speed and temperature. The mixer saves recipes for each product. This keeps every batch the same. Managers can watch and control the mixer from far away. These features help stop mistakes and keep things running well.

Tip: Automation in detergent powder mixers means fewer mistakes and less waiting. Factories can make more powder in less time.

Cost Savings

Lower Labor

Factories that use a detergent powder mixer need fewer workers. Machines do most of the hard work. Workers do not spend hours stirring powder. They do not need to check the powder all the time. This lets companies move workers to other jobs. Mixing by machine uses less energy. The mixer works fast and does not waste power. Some mixers have smart controls. These controls turn off the mixer when mixing is done. This saves time and electricity.

Tip: Using machines for mixing helps companies spend less on workers and energy.

Resource Optimization

A detergent powder mixer helps companies use materials better. The mixer blends powders evenly, so less gets wasted. Factories can make small or large batches with good quality. When every batch is right, companies throw away less product. This saves money and keeps things running well.

Stainless steel mixers save even more money. These mixers last 20-30 years. Other mixers last only 5-10 years. Stainless steel does not rust, stain, or scratch. The smooth surface makes cleaning easy. It keeps the mixer in good shape. A report says companies with stainless steel mixers spend 40% less on repairs. Stainless steel mixers can handle high heat and tough jobs. Many makers offer help and spare parts. This keeps the mixer working for many years.

Stainless steel mixers last longer and need fewer repairs.

Easy cleaning saves time and keeps the factory safe.

Fewer repairs mean less downtime and more savings.

Detergent Powder Mixer Advantages

Versatile Applications

A detergent powder mixer is used in many fields. Companies use it to mix powders and granules for many products. The mixer makes sure the mix is even. This helps products be safe and good quality. Here are some fields that use these mixers:

Food Industry: Mixes flour, sugar, and spices for even taste.

Pharmaceuticals: Blends ingredients for correct medicine doses.

Chemical Industry: Makes cleaning agents, paints, and coatings.

Construction: Mixes cement, sand, and other building materials.

Many factories pick detergent powder mixers because they work with dry and wet stuff. These mixers can handle many products. This makes them a good choice for many jobs.

Custom Features

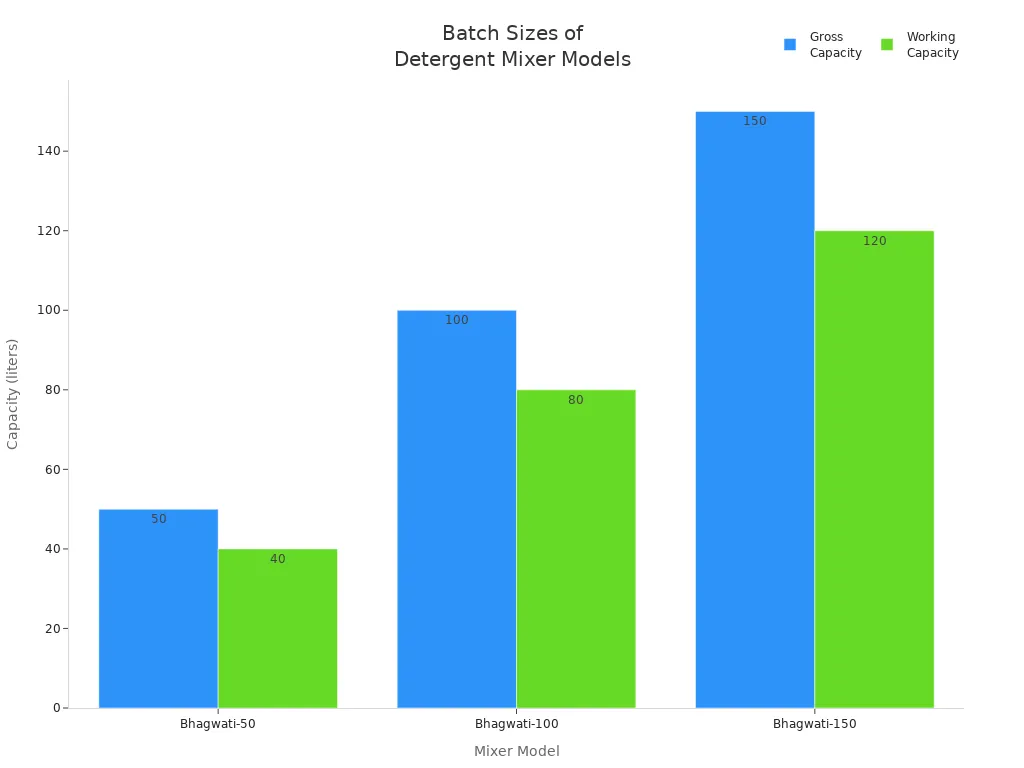

Makers can change a detergent powder mixer to fit their needs. They can pick the batch size, how much is automatic, and the mixing style. The table below shows how batch sizes change in different mixer models:

| Model | Gross Capacity (L) | Working Capacity (L) | Loading Capacity (%) |

|---|---|---|---|

| Bhagwati-50 | 50 | 40 | 80 |

| Bhagwati-100 | 100 | 80 | 80 |

| Bhagwati-150 | 150 | 120 | 80 |

Automation can include PLC controls with touch screens. Some mixers mix and granulate in one bowl. They also have easy ways to empty the bowl. Some mixers can do wet and dry mixing in one machine. Special impellers and chopper blades help mix fast and control size. These features let companies make different recipes with less work.

Good mixers use strong metals like stainless steel or titanium. This helps them last longer and work better.

Custom choices, like heating jackets or air seals, help with special jobs.

Easy cleaning and care mean less downtime and smooth work.

Tip: Picking the right features for a detergent powder mixer helps save time, cut waste, and make better products.

A detergent powder mixer helps companies make good quality products. It also helps them work faster and spend less money. Companies can get better results by doing a few things:

Look at what they need for work and money.

Make sure their process is good for the planet and makes good products.

Try new machines and check what is popular in the market.

If companies want help, they can use these resources:

Websites with how-to guides and videos.

Talk to experts who know about powder mixing.

Getting better machines and asking experts for help can give better results and save money for a long time.

FAQ

What types of detergent powder mixers are available?

Manufacturers make ribbon mixers, paddle mixers, V-shaped mixers, and double cone mixers. Each mixer works best for certain powders and batch sizes. Companies pick a mixer that fits what they need to make.

How does a detergent powder mixer improve product quality?

A detergent powder mixer mixes ingredients so they are even. This helps every batch have the same quality. Mixing well also stops clumps and dust. The final product is safer and works better.

Can a detergent powder mixer handle both wet and dry mixing?

Yes, many new mixers can mix wet and dry powders. Some mixers have special blades or bowls for different jobs. This lets companies do more with their machines.

How often should a detergent powder mixer be cleaned?

Workers should clean the mixer after each batch. Cleaning often stops germs from spreading and keeps the machine working well. Stainless steel mixers are easier and faster to clean.

What safety features do detergent powder mixers have?

Most mixers have safety covers, emergency stop buttons, and automatic shut-off systems. These features keep workers safe and help stop accidents while using the mixer.