LTB Machinery Liquid Soap Shampoo Detergent Heating Homogenizer Mixer Agitator Making Machine

库存: 0

Inquire

Add to Basket

It is the core equipment for the production of lotion, shampoo, gel, scrub.

Mixing:

Equipped with advanced Teflon stirring scrapers and fixed paddle for uniform mixing. Supports precise speed control.

Heating & Cooling:

Electric or Steam heating are optional. Electric heating can reach 100℃/200℃, Steam heating can reach 120℃.

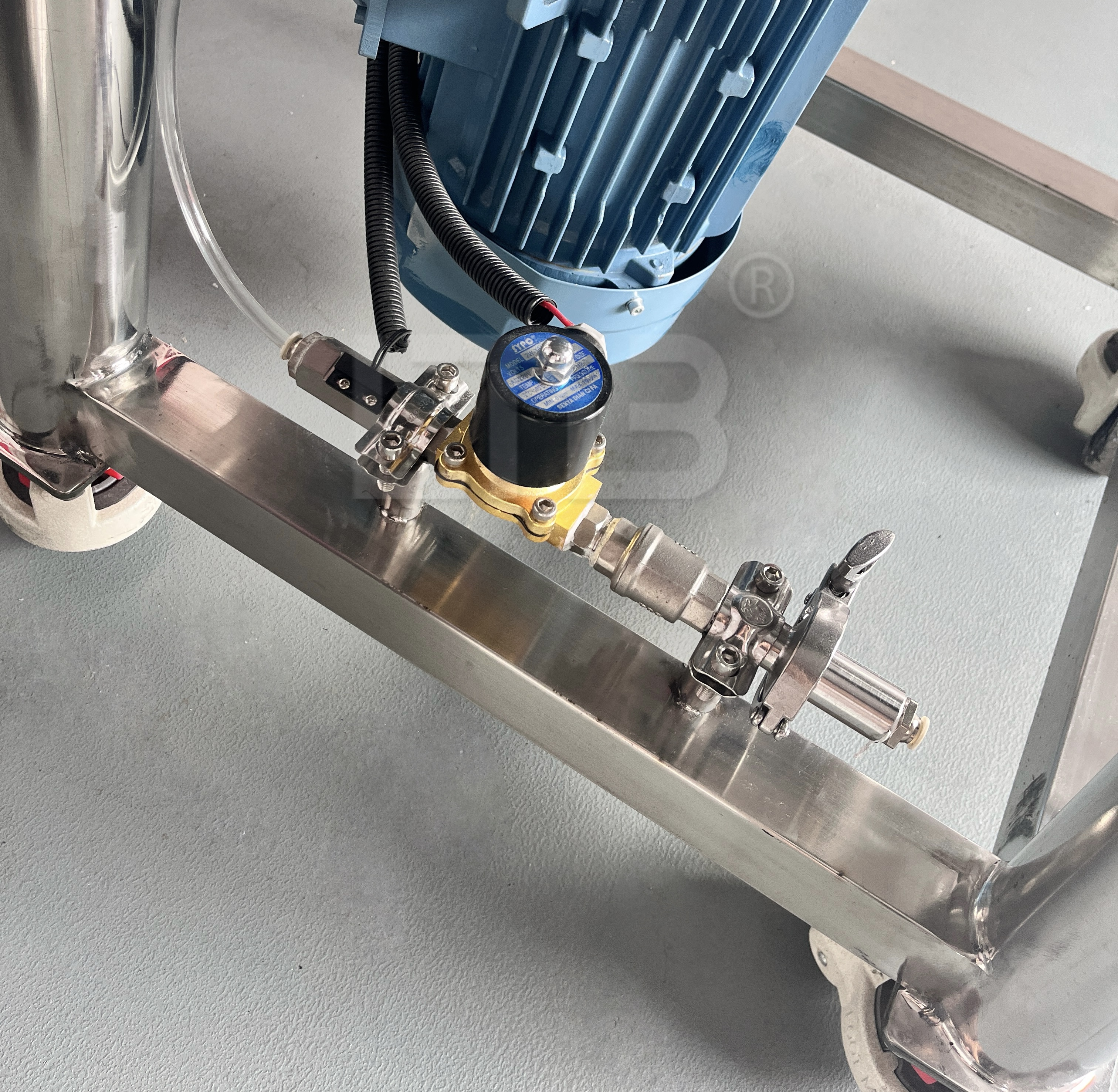

Homogenizer:

The homogenizer has strong tumbling effect and high shearing force, a frequency conversion speed adjustment controller satisfies various complicated ingredients.

Material:

All contact parts with materials are made of SUS 316L stainless steel and non-contact parts are SUS 304 stainless steel.

-

LTB-PM-25-300L

-

LTB

PRODUCTS DESCRIPTION

Stirring & Homogenizing

The stirring paddle mechanism and homogenization system work in tandem, which can strongly enhance the mixing effect.

The stirring paddle serves as the "basic guarantee" to ensure the overall uniformity of materials. Our mixing tanks are equipped with dead-angle-free welded stirring paddles and fixed paddles, which can prevent material residue, break up vortices, and improve the mixing effect more efficiently.

Homogenization acts as the "quality enhancement" to ensure the micro-level fineness and stability of materials. Our high-shear homogenizer is paired with a double-sided water cooling mechanical seal, featuring better cooling performance and a longer service life.

Combined, the stirring paddle and homogenization can meet the full range of application needs from ordinary liquid mixing to high-end fine chemical processes.

Dust-proof Design

Our mixing tanks adopt double-sided opening and half-opening designs, making it more convenient for workers to feed materials and easy to wash.

We have added a gasket to the tiny gap between the stirring paddle and the tank's shaft sleeve, which effectively prevents dust from the air and workshop environment from falling into the materials inside the tank through the gap.

This design is particularly important for industries with high material hygiene requirements such as food, daily chemicals, and pharmaceuticals. It can avoid dust-induced wear on moving parts, reduce corrosion caused by the mixture of moisture and dust, and effectively lower cleaning and maintenance costs.

Ball Valve Discharge

We adopt bottom-ball-valve discharge, whose core advantages focus on four dimensions: high discharge efficiency, reduced material residue, convenient operation, and higher adaptability. It is particularly suitable for liquids, pastes, and materials containing a small amount of particles.

The ball valve is installed at the bottom of the tank, with the discharge port flush with the lowest part inside the tank. Materials can flow naturally by their own gravity, resulting in faster discharge speed and no "stagnation dead corners".

Combined with the "sealed closing" feature of the ball valve, the bottom design can minimize material residue in the tank and reduce the risks of waste and contamination.