The A02 and A03 simple filling machines handle liquid and semi - liquid filling with different methods. The A03 is manually operated, giving operators direct control, ideal for small - scale production where hands - on flexibility for various containers is crucial. The A02, on the other hand, is pneumatically driven and foot - pedal controlled, especially suitable for paste - like products. It uses compressed air to draw and dispense product.

Both machines share significant advantages. They are cost - effective, perfect for small - scale businesses and start - ups on a budget. They are user - friendly, needing little training, and can handle diverse products and container sizes. Their simple structures with fewer components make maintenance easy. Thus, they are widely used in food, pharmaceutical, and cosmetic industries, as well as in handicraft and amateur production.

PRODUCTS DESCRIPTION

Advantages

Technical Parameters

| Model | A02 | A03 | |

| Filling Type | All product contact part are made of Stainless Steel 316L | Pneumatic | |

| Filling Volume | 5-50ml | ||

| Filling Speed | 10-20bottles/min | ||

| Hopper Capacity | 10L | ||

| Filling Accuracy | ±1% | ||

RELATED PRODUCTS

Brief Introduction

Advantages

Technical Parameters

Description

FAQ

| Effective Capacity | 5L | 10L | 20L | ||

| Material | All product contact part are made of Stainless Steel 316L | ||||

| Tank Design | Three layers, double jackets | ||||

| Heating Methods | Eelctric heating | ||||

| Electric Heating Power | 1KW | 3KW | 3KW | ||

| Mixing Design | Double way no-dead-angle mixing paddle with Teflon sraper | ||||

| Mixing Power | 0.4KW | 0.55KW | 0.55KW | ||

| Mixing Speed | 0-63rpm, customizable | ||||

| Mixing Motor | ABB or SIEMENS | ||||

| Homogenizer Design | High shear teeth-shape homogenizer | ||||

| Homogenizer Position | Bottom/upper/inline homogenizer+rotary pump circulation type | ||||

| Homogenizer Power | 1.5KW | 1.5KW | 2.2KW | ||

| Homogenizer Speed | 0-2960rpm, customizable | ||||

| Homogenizer Motor | ABB or SIEMENS | ||||

| Vacuum Pressure | -0.1Mpa | ||||

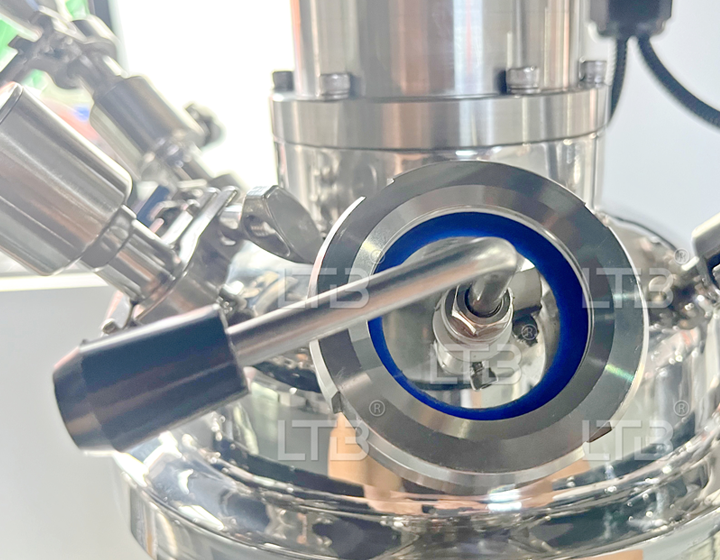

| Cover Type | Hydraulic lifting cover | ||||

| Tank Titling | More than 90 degree tank body titling | ||||

| Control Way | SIEMENS PLC control system and touch screen/push button | ||||

Homogenizer

The high shear emulsifying homogenizer head in the laboratory emulifier mixing machine is designed to break down and mix substances. This small scale cosmetic cream ointment paste making mixer machine uses high speed rotation to create intense shear forces. This allows for efficient emulsification and homogenization of liquids, powder and solids, ensuring fine and uniform mixtures.

Mixing Pads

The emulsifier features two - way agitation with Teflon scrapers. The two - way stirring design enables more comprehensive and intensive mixing of materials from different directions, ensuring uniform emulsification. The Teflon scrapers, with their excellent chemical resistance and non - stick property, effectively prevent materials from adhering to the vessel walls. This not only improves material utilization but also simplifies cleaning. Overall, this combination boosts emulsification efficiency and product quality while reducing maintenance efforts.

Cover Accessary

The vacuum emulsifier mixer cover is equipped with several crucial components. The visual window allows operators to observe the emulsification process clearly, ensuring quality control. The pressure relief valve with a filter safeguards the equipment by releasing excess pressure while filtering impurities. The vacuum valve helps create a vacuum environment, improving emulsification efficiency. These components together enhance the functionality, safety, and quality of the emulsification process.

Vacuum Pressure Gauge

This emulsifier is equipped with an imported vacuum gauge. Engineered with advanced technology, it offers significantly higher precision compared to regular gauges. The high - precision vacuum gauge allows for extremely accurate monitoring of the vacuum level within the emulsifier. This ensures optimal conditions for emulsification, enhancing product quality and consistency. It also helps in early detection of any vacuum - related issues, enabling timely maintenance and minimizing production disruptions.

Q: What is your company's history and experience in manufacturing cosmetics production machinery?

A: Our company has been in the cosmetics/chemical/pharmaceutical/food machinery manufacturing industry for more than 26 years. We've served numerous clients globally, providing customized solutions for various production scales, from small - batch handmade cosmetics to large - scale industrial production.

Q: Where are your manufacturing facilities located?

A: Our main manufacturing facilities are situated in Guangzhou and Jiangsu Province, China.

Product - Related

Q: Can your machines produce different types of cosmetics, like creams, lotions, and gels?

A: Yes, our machinery is highly versatile. With adjustable parameters such as speed, temperature control, and mixing time, our vacuum emulsifiers, homogenizer liquid mixing machine, bottle filling capping labeling machines, tube filling sealing machine, etc., can handle the production of cosmetic, creams, lotions, gels, and even more complex formulations like serums.

Q: How do I ensure the quality of the products produced by your machines?

A: Our machines are designed with precision engineering. They feature advanced mixing mechanisms to guarantee uniform dispersion of ingredients. Additionally, we use high - quality materials that are compliant with food and cosmetic safety standards, preventing any contamination during production.

Q: What is the production capacity of your equipment?

A: It varies depending on the specific model. For example, our small - scale emulsifiers can produce batches of 5 liters, while large - scale industrial models can handle up to 5000 liters per batch. Filling machines also have different output rates, from 10 bottles per minute for small - scale operations to 100 bottles per minute for high - speed production lines.

Order and Delivery

Q: What is your minimum order quantity?

A: The minimum order quantity (MOQ) depends on the product. For standard models, the MOQ is usually 1 unit(s). However, for customized products, we can discuss and determine a suitable quantity based on your specific requirements.

Q: How long does it take to deliver the machines after placing an order?

A: For in - stock items, delivery can be arranged within 7 working days. For custom - made machinery, the production and delivery time typically range from 4 weeks to 2 months, depending on the complexity of the design and production process.

Q: What are your payment terms?

A: We usually accept payments through T/T (Telegraphic Transfer). For regular customers, we may also consider other payment methods after negotiation. A 40% deposit is required upon order confirmation, and the balance is due before shipment.

After - sales Service

Q: Do you provide installation and training services?

A: Yes, we offer on - site installation and training services for our customers. Our technicians will ensure that the machines are properly installed and operational. They will also train your staff on machine operation, maintenance, and basic troubleshooting.

Q: What is your warranty policy?

A: Our products come with a standard warranty of 1 year. During this period, we will repair or replace any defective parts free of charge, excluding damages caused by improper use or force majeure. We also provide long - term technical support and supply of spare parts.