Q: Are you a factory?

A: Yes. We are indeed a factory with over 26 years of manufacturing experience. One facility is located in Jiangsu Province, and the other is in Guangzhou, adjacent to our office.

Q: I'm new to the industry but planning to set up a factory, what can I do?

A: We will design the most appropriate proposal based on your unique situation, including daily production needs, raw material formulas, factory layout, and more. Additionally, we can introduce you to top-tier suppliers of raw materials, bottles, labels, and other essentials if required.

Product - Related

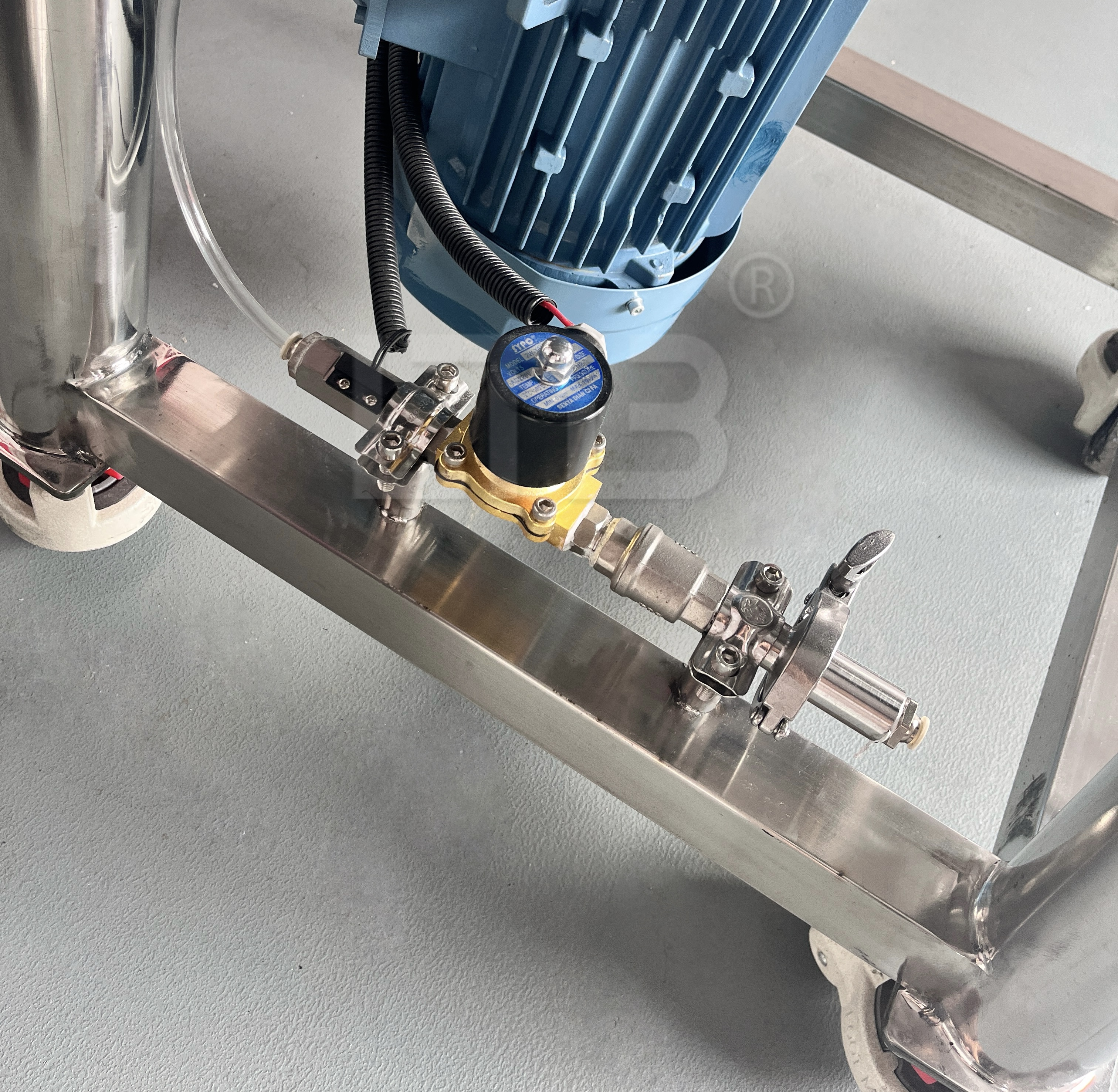

Q: Is the mixing strength of the mixer sufficient?

A: Yes. The speed of mixing and homogenizing can reach 63rpm and 2960rpm respectively. The mixing paddle matches the fixed paddle, and the homogenizer has a super rolling and mixing effect, which can mix your product more evenly and cut more finely, especially for high-viscosity products.

Q: Is it possible to adjust the heating temperature, and what is the maximum adjustable temperature?

A: Yes. The temperature can be adjusted according to your formula. We have electric and steam heating, passing water or oil into the double jacket can reach a temperature of 100℃ or 200℃ respectively for electric heating, passing steam into double jacket can reach temperature of 120℃.

Q: What's the cooling method?

A: The cooling method is water cooling, whether you choose electric or steam heating, passing water into the jacket allows cooling to room temperature, while passing ice water into it enables cooling to a temperature below room temperature.

Q: Does the mixer comply with cosmetics production standards?

A: Yes. All contact parts with materials are 316L materials and non-contact parts are 304 stainless steel. All connecting components are quick-connect fittings. The interior of the tank body features mirror polishing, with a surface roughness of Ra ≤ 0.4μm, which complies with EU cosmetic standards.

Order and Delivery

Q: What's the delivery time for shampoo mixer?

A: Normally the delivery time is around 45-50 working days, which depends on your configurations, functions and voltage according to your customization.

Q: What are your payment terms?

A: We usually accept payments through T/T (Telegraphic Transfer). A 40% deposit is required upon order confirmation, and the balance is due before shipment.

After - sales Service

Q: How do you control the quality before delivery?

A: Initially, our component and spare parts providers test their products before supplying them to us. Furthermore, our quality control team rigorously tests the machine's performance and running speed before shipment. We invite you to visit our factory to personally verify the machines. If your schedule is tight, we will record a video of the testing procedure and send it to you.

Q: What's the warranty of mixer?

A: Our warranty period is one year. Even after the warranty expires, we offer lifetime after-sales service, ensuring that we are always available to assist you whenever needed. If the problem is straightforward, we will create a solution video for you. If the video does not suffice, we will send an engineer to your factory.